Products

Laser and video inspection systems for geometry and surface defects of rolled metal

MRT-1420

Automatic geometric parameters control system for large diameter pipes

Inline measurement of up to 14 parameters of large diameter straight- and spiral-welded pipes.

Measured parameters:

MRT-530

Automatic geometric parameters control system for small and medium diameter pipes

Automatic geometry control of HF welded pipes of small and medium diameter.

Measured parameters:

MRT-300-Surface

Mandrel surface defects inspection system

Creates a 3D surface map of mandrels and seamless pipes with defect recognition.

Measured parameters:

MRT-Hot

Hot seamless pipe geometry control system

Diameter and wall thickness control of hot seamless pipes directly in the mill.

Measured parameters:

MRT-Video

Pipe length video control system

Video recording and measurement of pipe length on HF pipe mills.

Measured parameters:

MRS-07

Scanning/tracking module

Laser scanning of weld geometry with seam tracking for pipes, plates and profiles.

Measured parameters:

MRT-Manual

Manual pipe ends measuring device

Portable gauge for fast checks of pipe end diameter and ovality.

Measured parameters:

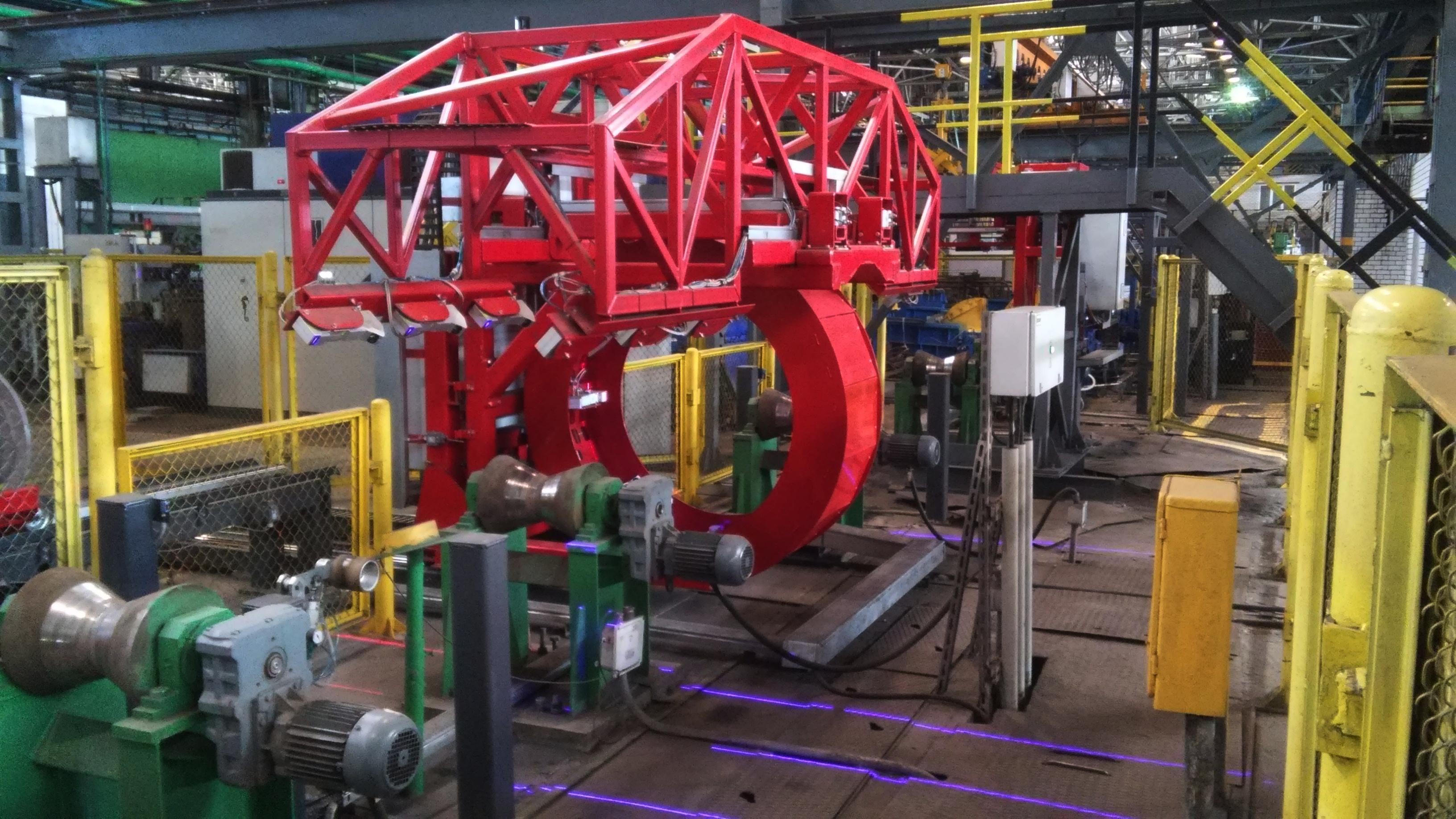

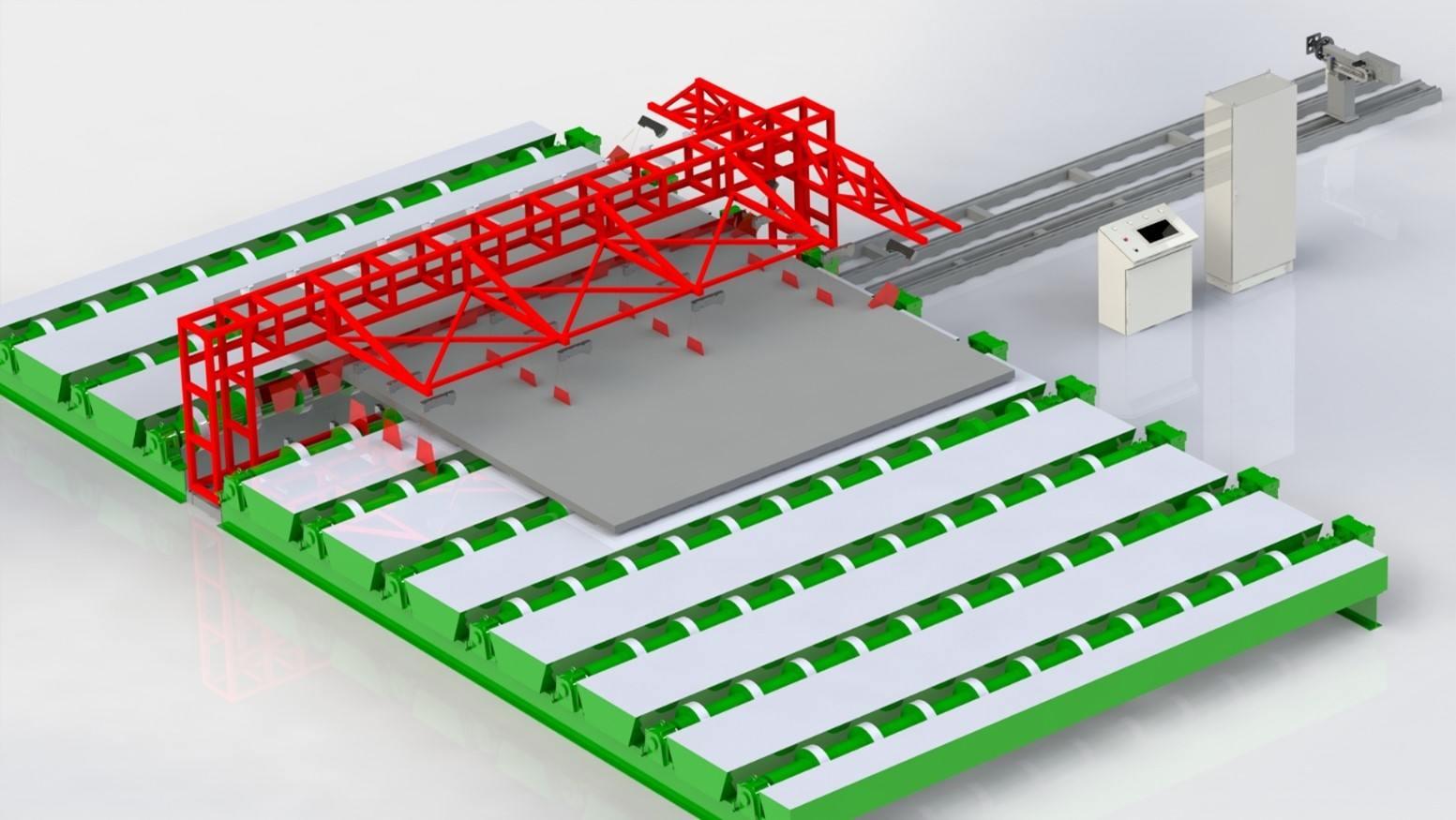

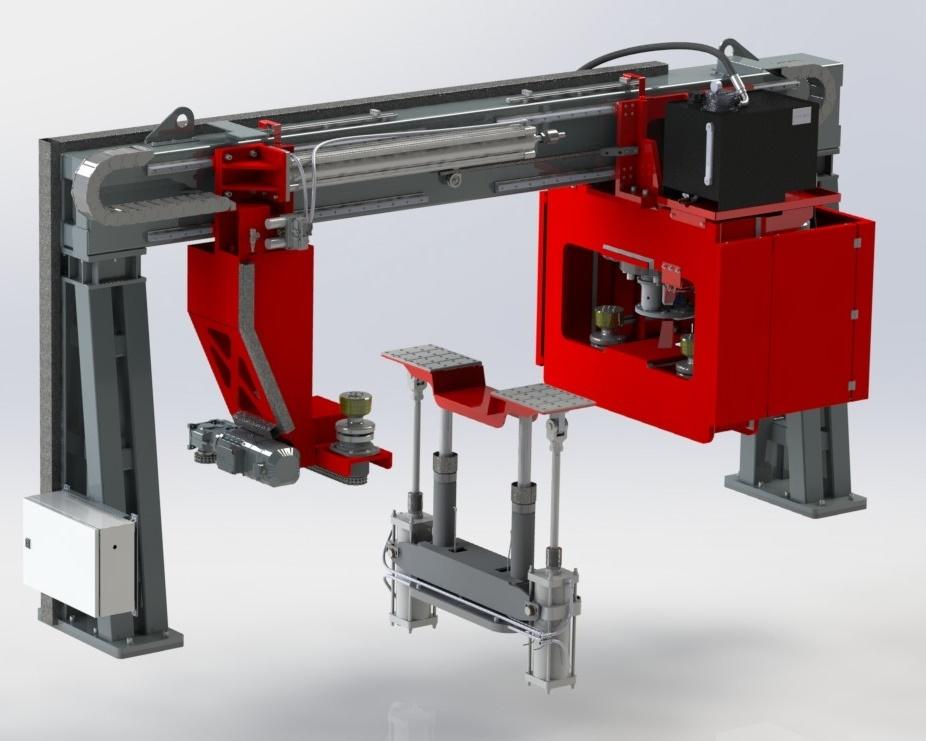

MRL-5000-Surface-Video / SIGL

Automatic plate geometry and surface defects control system

Laser and video inspection of plate geometry, bevel and surface defects.

Measured parameters:

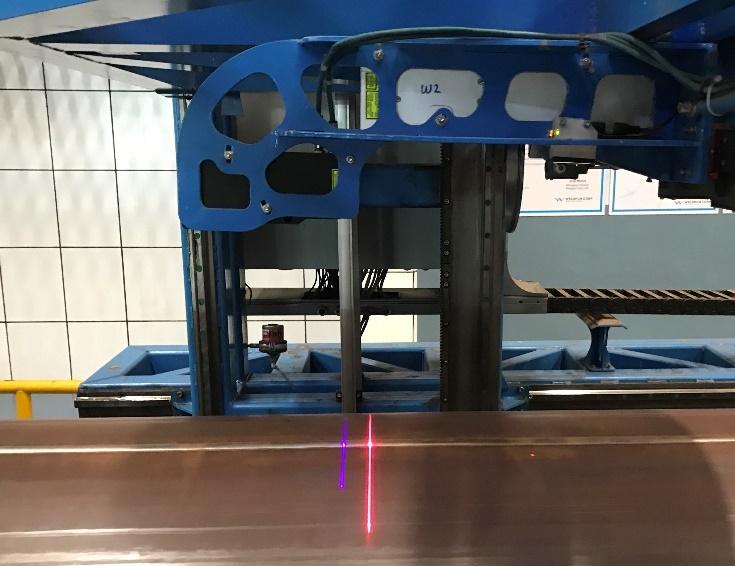

MRL-Edges / Kromkomer

Plate side chamfer geometry control system

Precision measurement of plate width, bevel angle and straightness.

Measured parameters:

MRL-Mark / KMM

Plate marking machine

Automated plate marking with quality verification of the imprint.

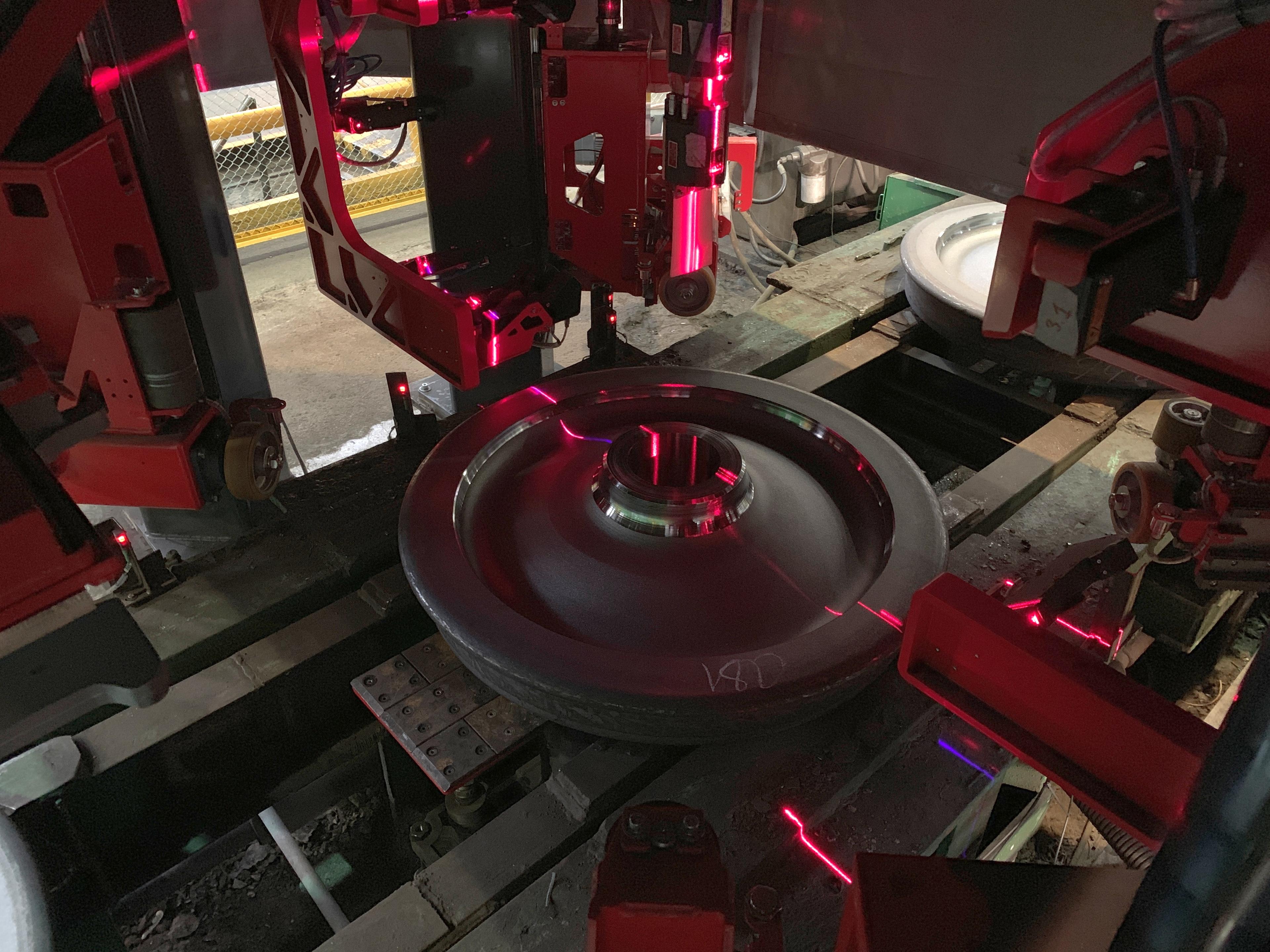

MRK-1200

Railway wheel geometry control system

Measures the full profile of railway wheel rim, disc and hub.

Measured parameters:

MRK-Mark-Surface / Kleymitel

Automatic railway wheel marking system

Automated branding of wheels with engraving quality and surface defect control.

Measured parameters:

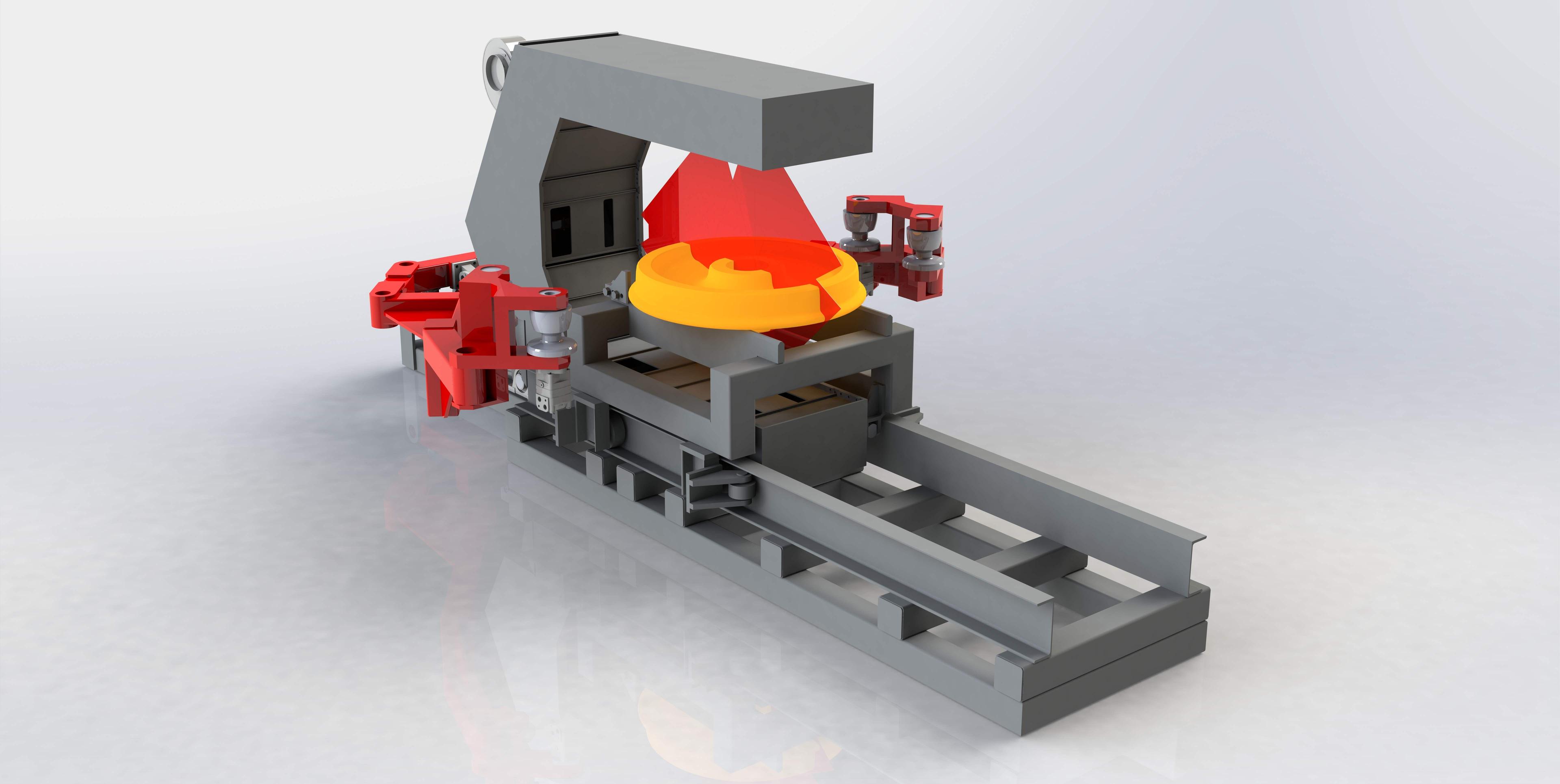

MRK-1200-Hot

Hot railway wheel geometry control system

Geometry control of hot railway wheels at axle press shops.

Measured parameters:

MRP-600-Surface-Hot / Profiler

Automatic hot rolled profile geometry and surface defects control system

Geometry and surface inspection of hot rolled rails, channels and beams.

Measured parameters:

MR-US-01

Ultrasonic defectoscopy and geometry control system for aluminum billets

Ultrasonic flaw detection and geometry control of aluminium billets and ingots.

Measured parameters: