Purpose

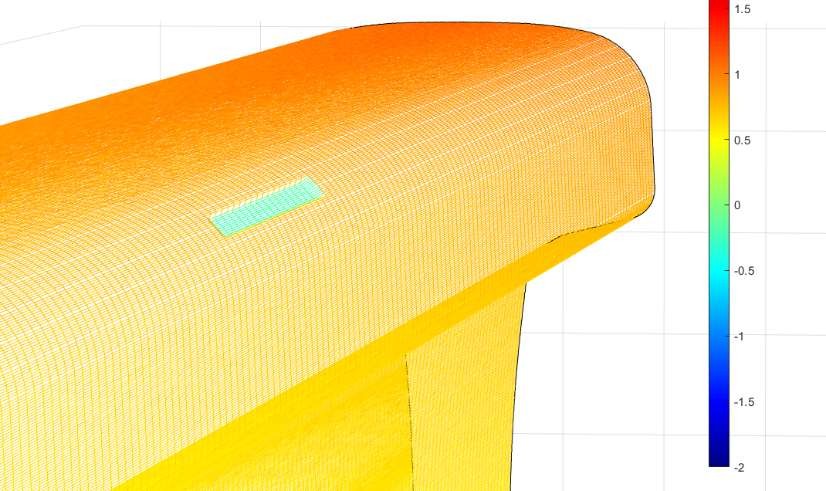

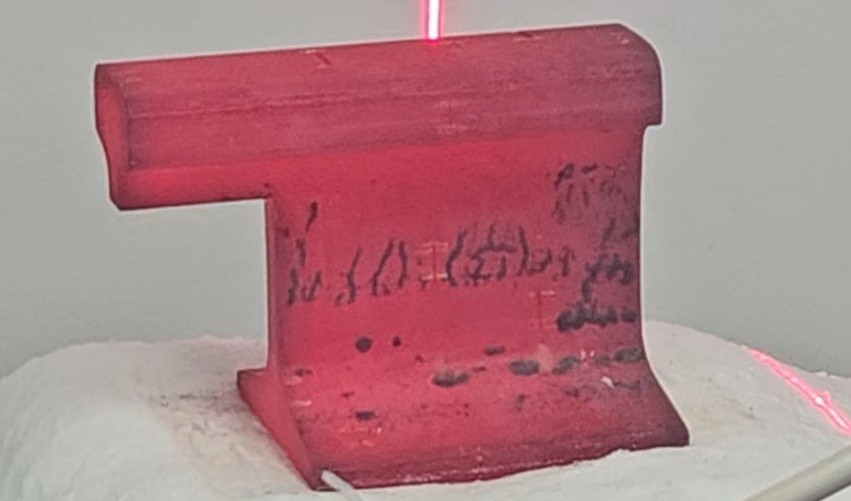

The system provides automatic measurement of geometry and detection of surface defects of hot rolled profiles (rails, I-beams, channels, etc.) directly after rolling.

Key features

- Automatic measurement of any rolled profile: rails (GOST 51685, EN 13674, AREMA 2020, UIC 860-0), I-beams (GOST 57837), channels (GOST 8240), round bars, etc.

- Operation at line speeds up to 6 m/s and product temperature up to 1200 °C.

- Measurement of geometric parameters according to required standards.

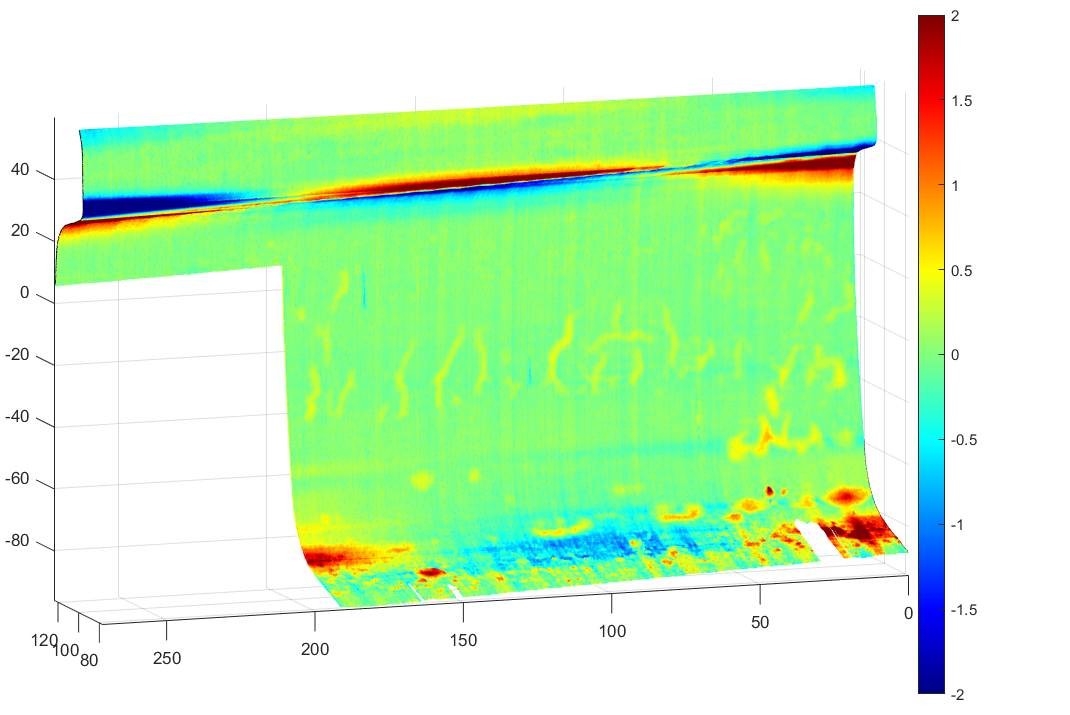

- Detection of defects on 100% of the product surface: depth from 0.3 mm, size from 1 × 2 mm.

- Scanning frequency up to 10 000 Hz; surface resolution 0.15 × 0.6 mm.

- Real-time processing on a dual-processor server (24 cores × 2400 MHz) with RAID controller.

- Web client interface for visualization and control.

Main specifications

| Parameter | Value |

|---|---|

| Control objects | Rails, channels, I-beams, sections, hot |

| Zone size, mm | 300 × 600 |

| Geometric parameter measurement | Up to 31 parameters depending on profile type |

| Measurement methods | Laser 2D scanners |

| Measured parameters | 3D model, defects |

| Operating mode | 24/7 |

| Installation location | Rail mill, section mill |

Detailed defect recognition

Defects from 1 × 1 mm in size with depths from 0.3 mm.

Product catalog