Description

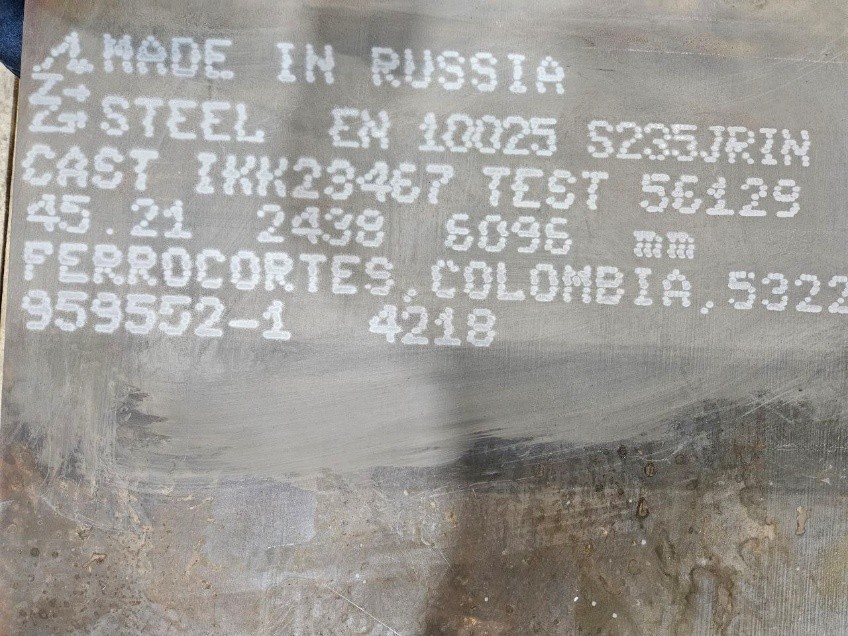

The plate marking machine is designed for automatic, simultaneous stamping and marking of steel plates in a rolling production line.

Advantages

- Fully automatic stamping and marking of sequential plates on the conveyor.

- Fast operation on stationary plates, ensuring consistent quality and independence from vibration or line speed.

- Flexible configuration of text: font selection, frames, barcodes and QR codes, logos, etc.

Technical specifications

| Parameter | Value |

|---|---|

| Plate dimensions | Width up to 2600 mm, thickness up to 100 mm, length up to 18 m |

| Plate hardness | up to 500 HB |

| Marking time per plate | ≤ 30 seconds |

| Throughput | ≥ 120 plates per hour |

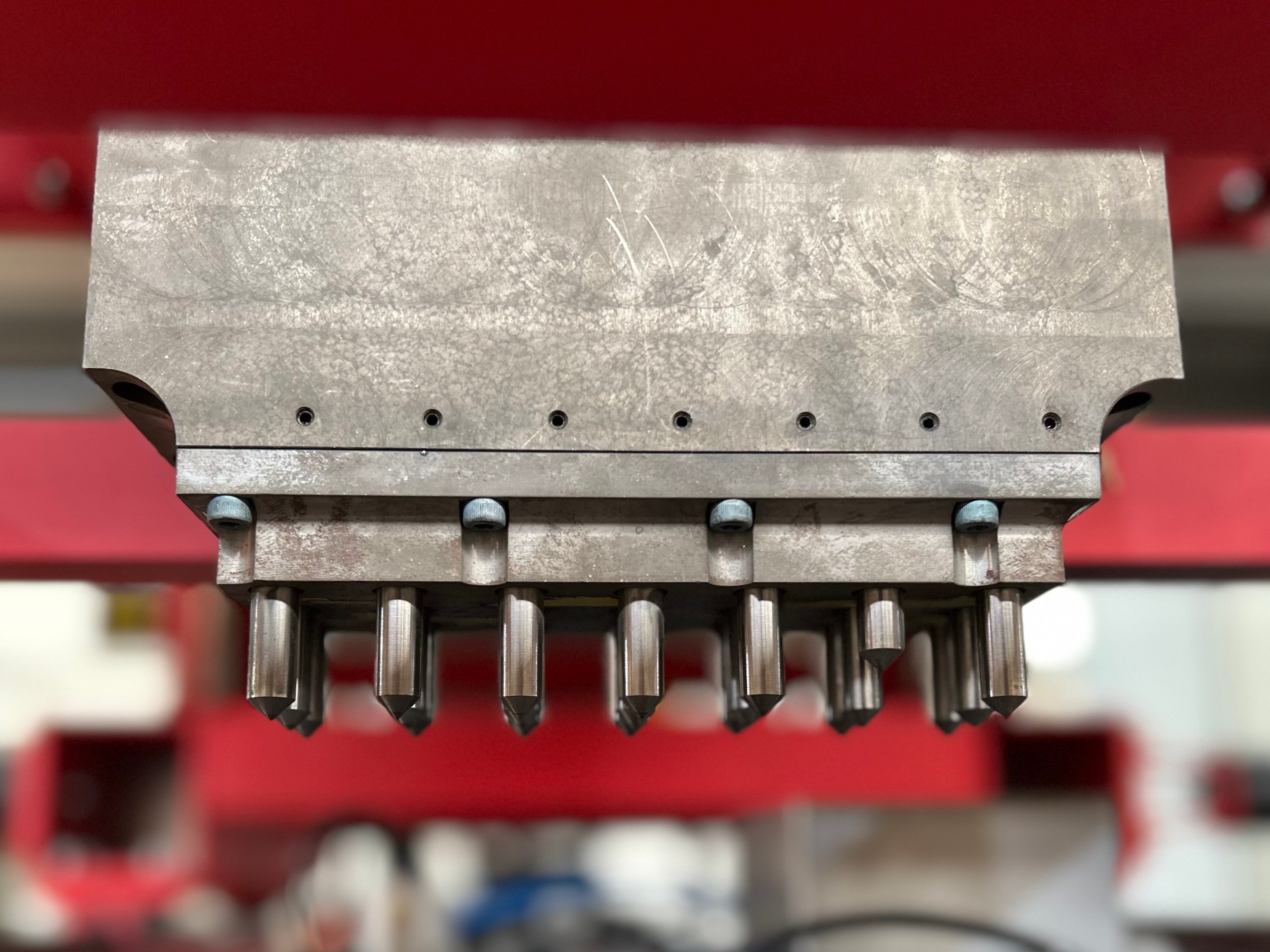

| Stamping head | 3 rows of 7 pins each, motion in two axes (across and vertical), depth ≥ 0.25 mm, 3 lines |

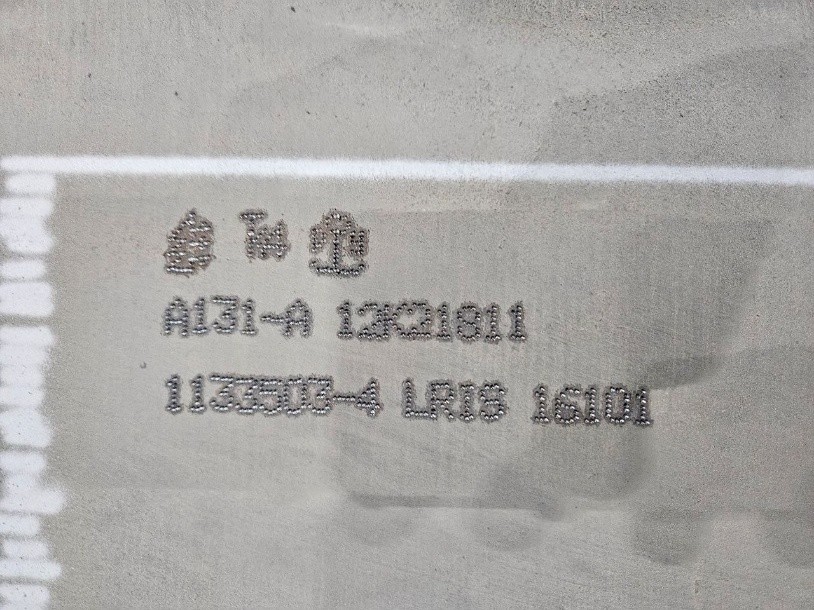

| Marking head | 3 modules with 7 nozzles each, motion in three axes (across, along, vertical), dot diameter 5–7 mm, 9 lines |

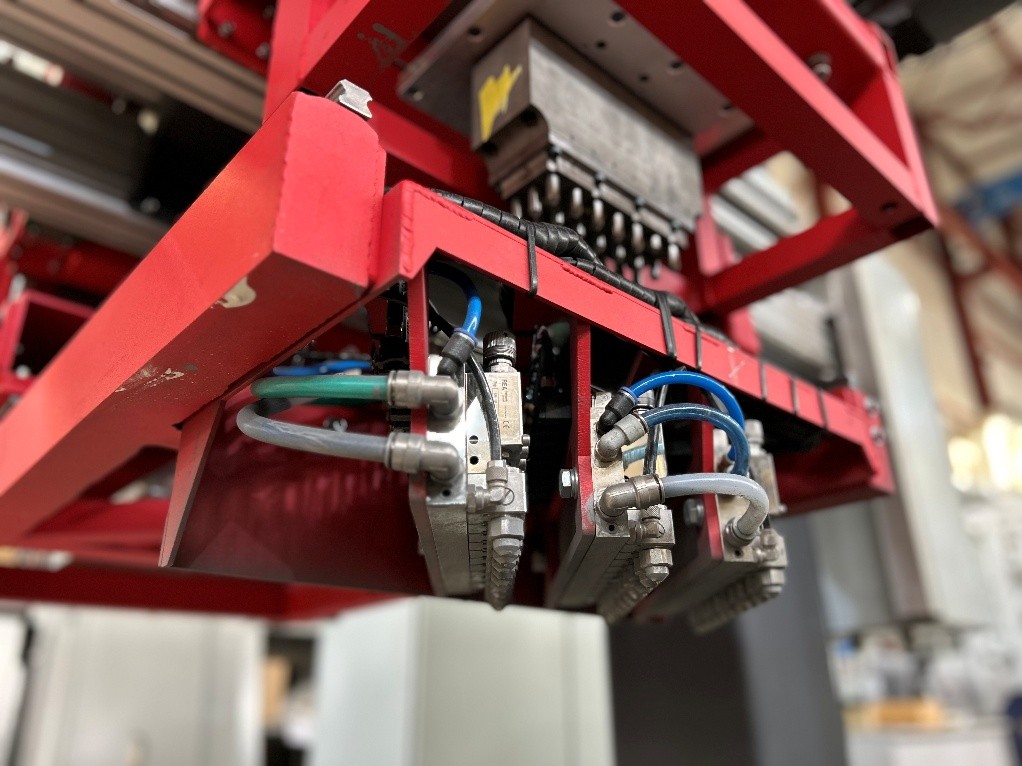

The system includes two independent heads (stamping and marking) with dedicated motion coordinates across the entire work area.

After the plate stops, the marking head prints a frame, after which both heads independently move to their target areas and finish stamping and marking in no more than 14 seconds:

- the stamping head sequentially applies 3 lines of 7 characters each (≈12 seconds) and moves to the next position,

- the marking head prints 3 lines up to 1000 mm long (≈2 seconds + 1 second to move between lines).

Product catalog