Purpose

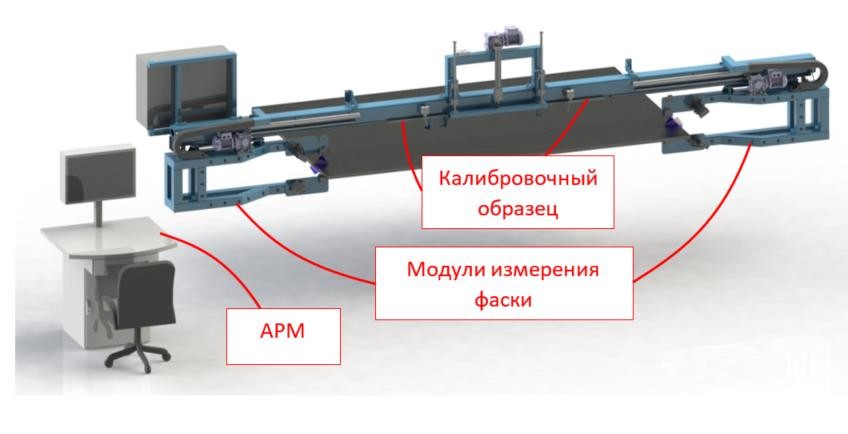

The system performs automatic, contactless measurement of the side chamfer geometry of metal plates during production, operating 24/7 immediately after cutting and edge preparation.

Main specifications

| Parameter | Value |

|---|---|

| Control objects | Plates |

| Width, mm | from 1500 to 3200 |

| Measurement methods | Laser 2D scanners |

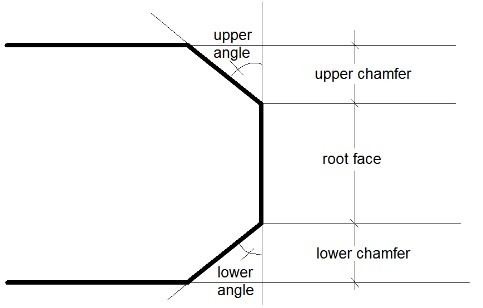

| Measured parameters | Wall thickness, plate width, chamfer angles, chamfer shelf width (up to 3 shelves) |

| Measurement accuracy | up to ±0.05 mm |

| Alarm | Alerts when chamfer parameters deviate from tolerances |

| Operating mode | Fully automatic, 24/7 |

| Installation location | Pipe mill |

Equipment composition

- High-resolution laser 2D scanners.

- Moving chamfer measurement modules on guides with servo drives and linear encoders.

- Calibration specimen (reference chamfer) with an automated loading device.

- Operator workstation with data processing and visualization software.

Product catalog