Purpose

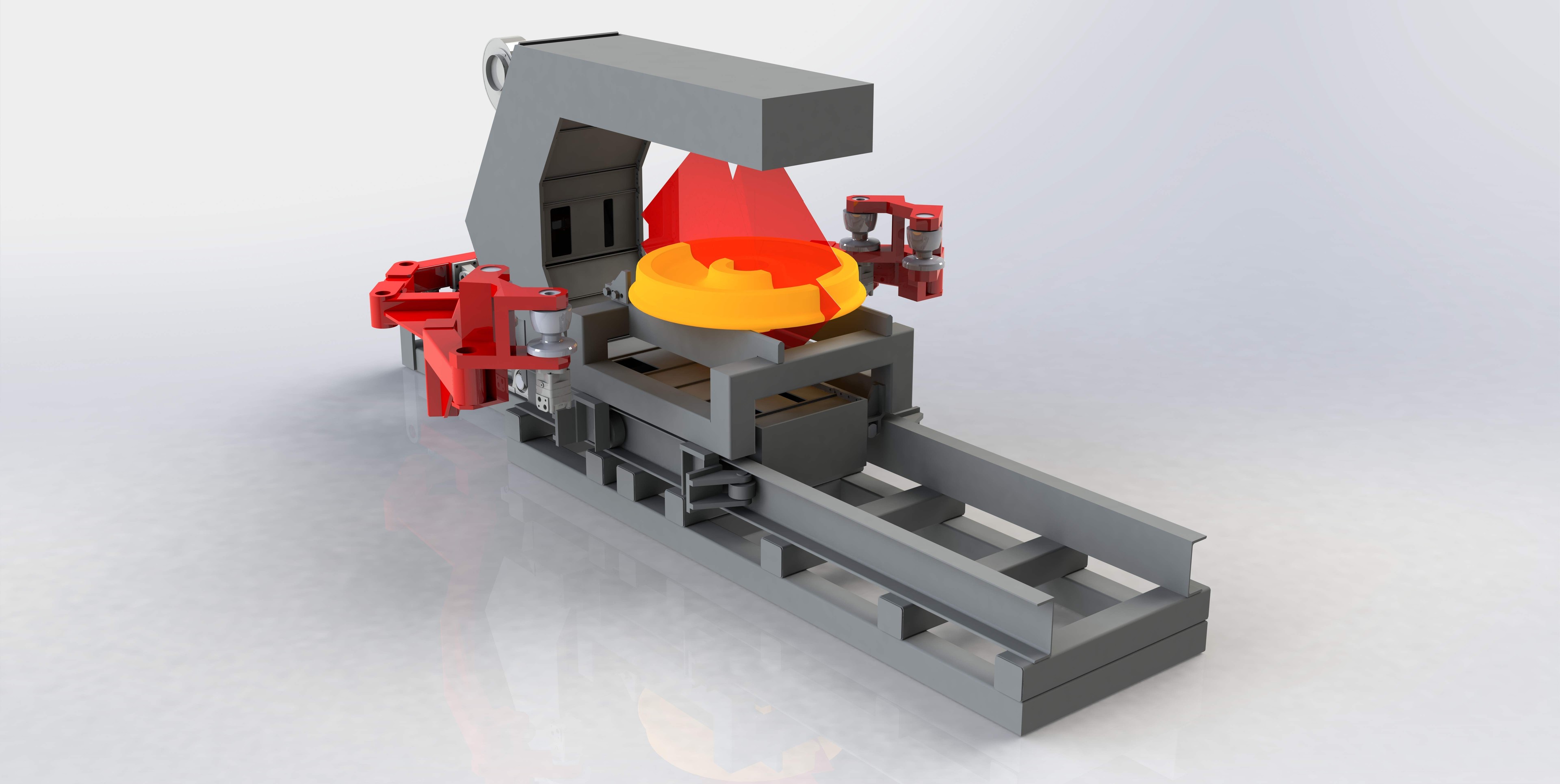

The system is designed for automatic measurement of geometric parameters of hot railway wheels immediately after rolling.

Key features

- 100% laser control of every hot wheel’s geometry.

- Protective shutters and an air knife shield the laser scanners from hot scale.

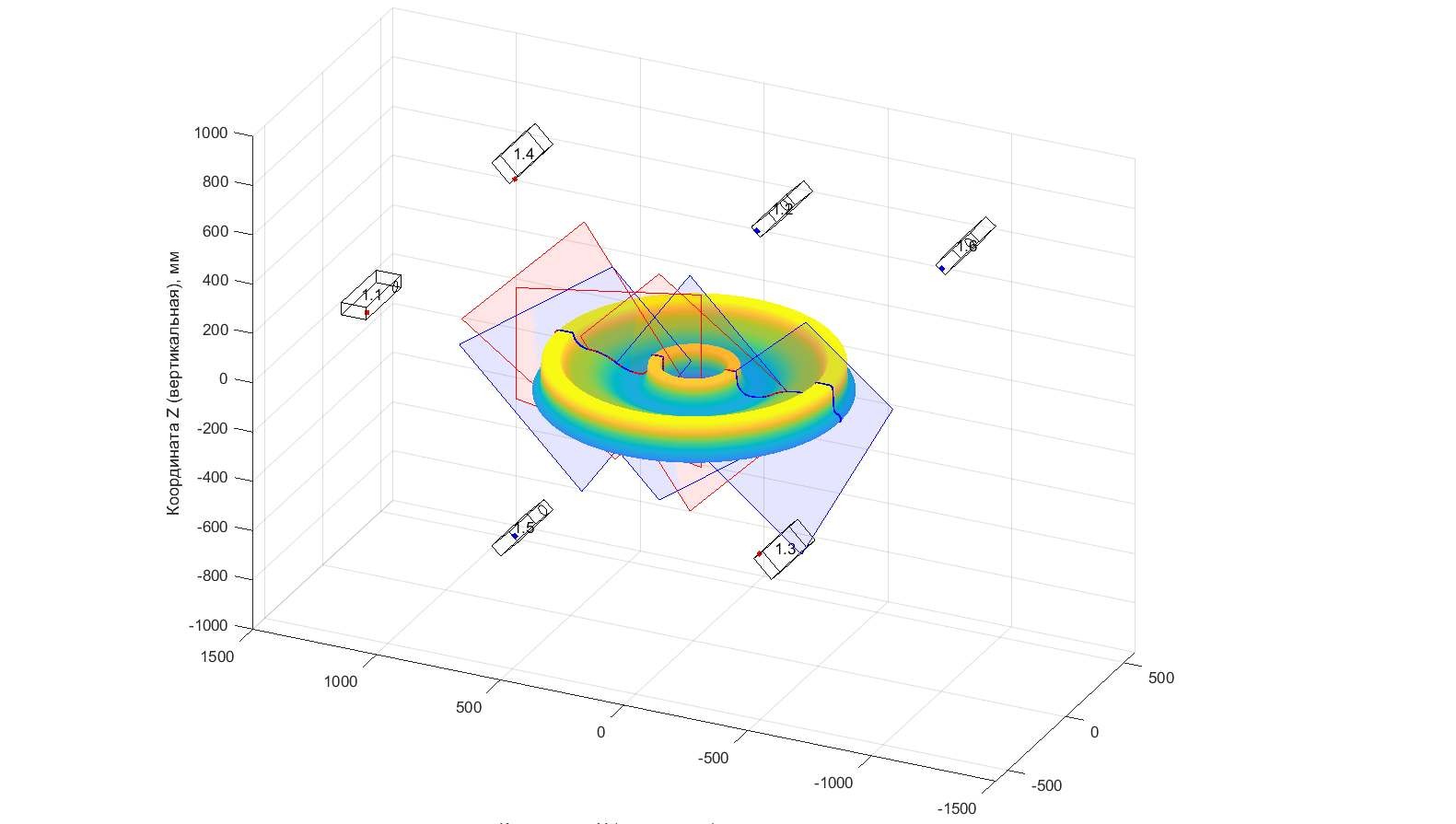

- No blind spots: a complete digital 3D wheel model is generated.

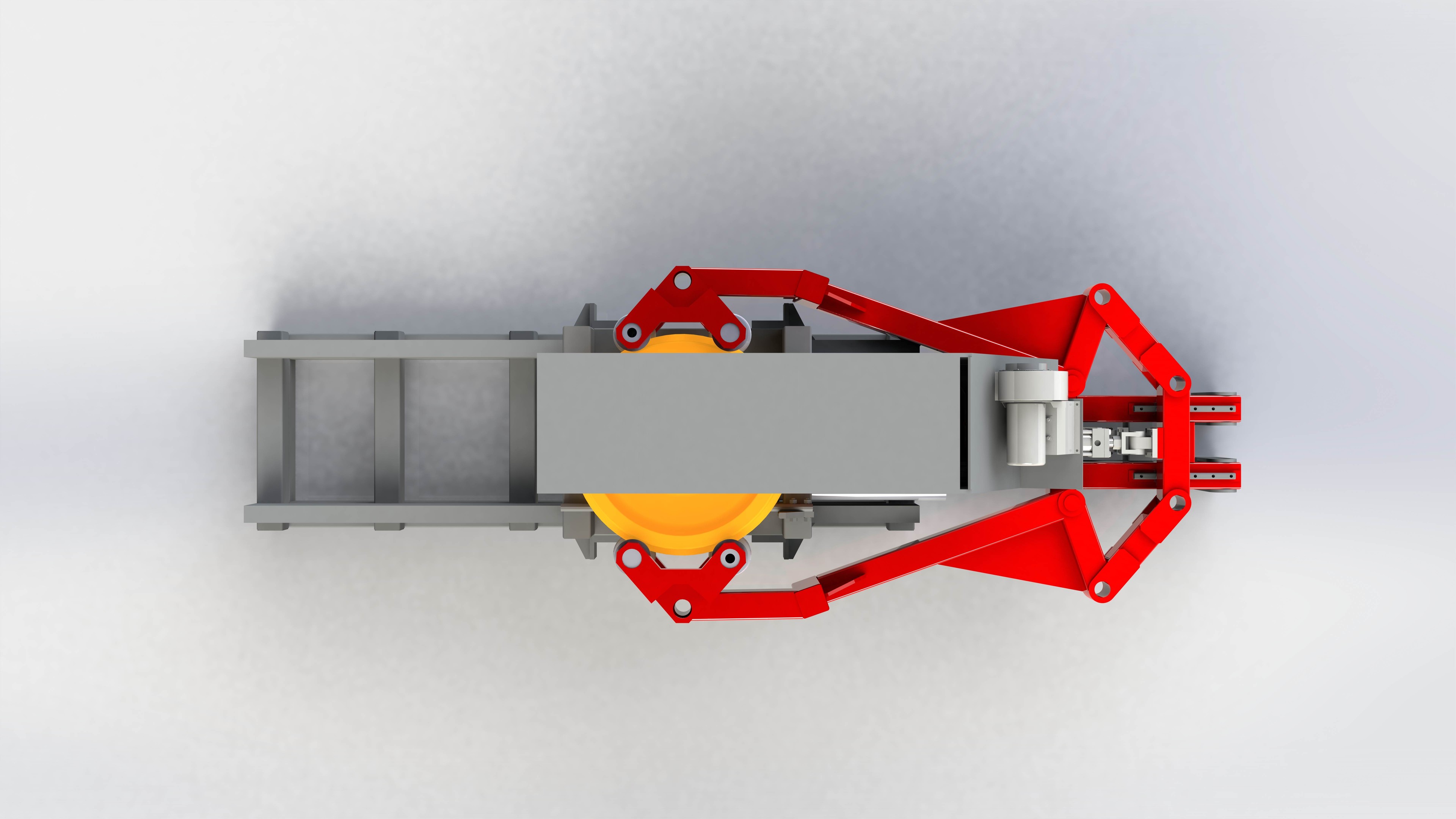

- Algorithmic wheel centering (combined with mechanical centering) using profile sensor data.

- High operational reliability thanks to separating the measuring module from the base via protective enclosures and a rotary mechanism.

Main specifications

| Parameter | Value |

|---|---|

| Wheel characteristics | Diameter 700–1200 mm, temperature 850–1000 °C |

| Measurement principle | 2D laser triangulation, full 3D wheel model acquisition |

| Measurement frequency | up to 230 Hz |

| Number of radial sections (axes) | ≥ 100 (every 3.6°) |

| Measurement time per wheel | ≤ 23 seconds (excluding material handling) |

| Measured parameters | Rim, disc, hub, diameters, thickness/width—up to 17 parameters |

| Geometry measurement accuracy | 0.5 mm |

| Control objects | Hot railway wheels |

| Operating mode | 24/7 |

| Installation location | Wheel rolling shop |

Product catalog